|

arious recipes were used for composition, but most included sawdust, cornstarch and glue, ingredients Canada had in abundance. The doll industry was the largest consumer of cornstarch in Canada before the Second World War. arious recipes were used for composition, but most included sawdust, cornstarch and glue, ingredients Canada had in abundance. The doll industry was the largest consumer of cornstarch in Canada before the Second World War.

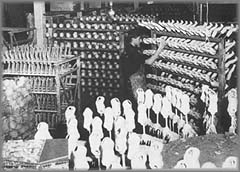

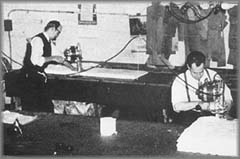

The ingredients were mixed together, then the paste was spread onto brass moulds and heated. Once dry and hard, the two halves were glued together and prepared for painting. The surface was coated with glue to make it hard and smooth. At least two coats of paint were applied before facial features were painted.

Dolls had all-composition bodies or stuffed cloth bodies with composition arms and legs. They wore mohair wigs or had hair painted on. The manufacture of composition dolls was labour-intensive and provided jobs at a time when jobs were hard to find. In 1936, the Reliable Toy Company produced 1.5 million dolls in 300 models.

|